Welcome to Roadlab

Rock Mechanics

We’re proud to introduce Roadlab Rock Mechanics, a state-of-the-art facility dedicated to the testing and analysis of rock and geological materials.

Our new lab combines expert knowledge with advanced equipment to deliver accurate, reliable results for the mining, geotechnical, civil, and construction industries.

X-Ray Diffraction | Uniaxial Compressive Strength | Point Load | Slake Durability

REACH OUT

A One-of-a-Kind Rock Laboratory in Africa

At Roadlab Rock Mechanics, we’re proud to operate the first X-Ray Diffraction (XRD) unit of it's kind in Africa — and the first to support South Africa’s SANRAL XRD specification.

What this means for our clients

We now offer mineral testing previously unavailable in Africa — high precision mineral identification and quantification for rock core analysis, soil characterisation, mineral exploration and more.

Capable of Unconfined Compressive Strength (UCS) Testing, Point Load Testing (PLT) and Slake Durability testing, this specialised facility offers unmatched insight into the behaviour and quality of materials used in mining, geotechnical design, road layerworks and concrete production.

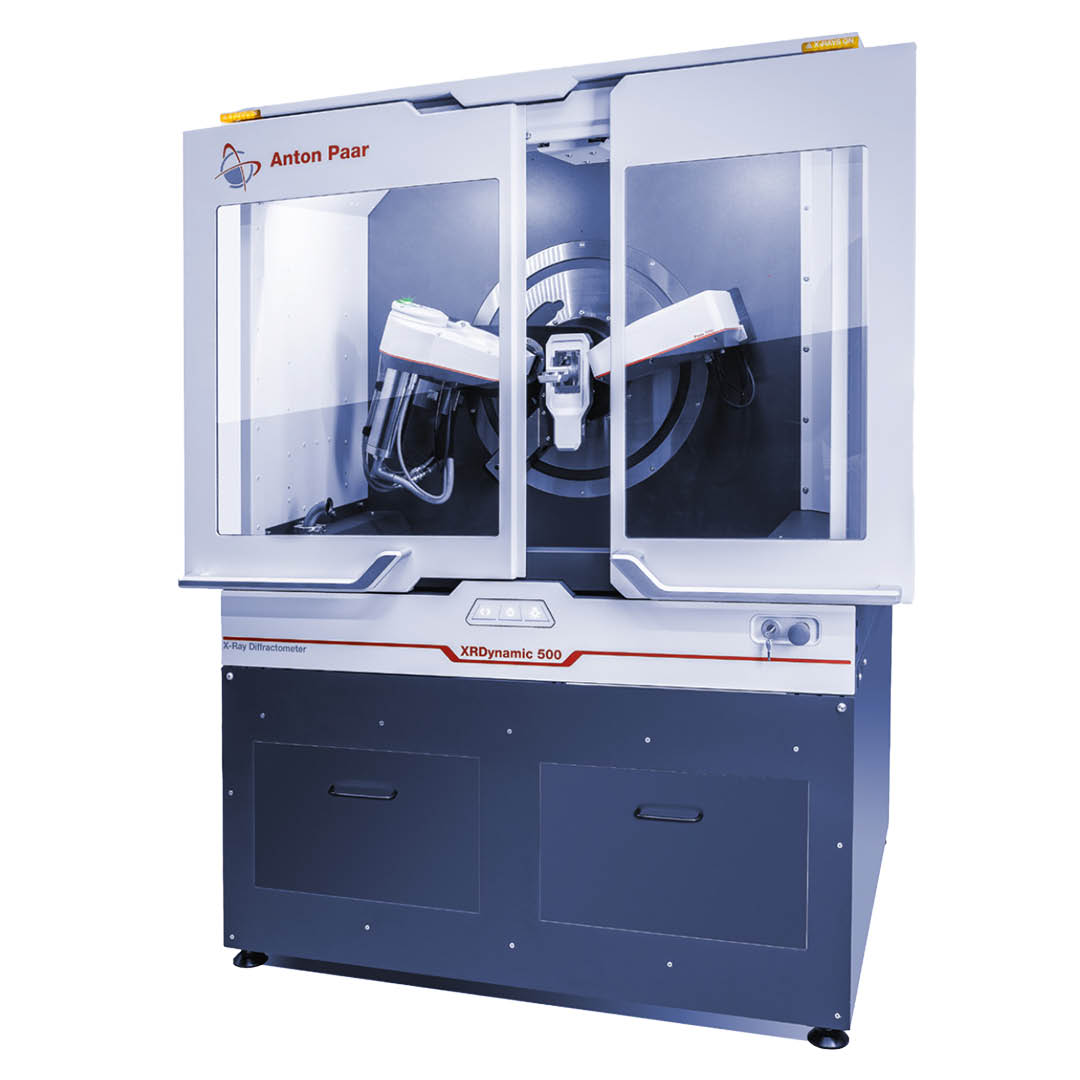

X-Ray Diffraction (XRD)

The XRDynamic 500 is Anton Paar’s first floor-standing powder diffraction unit launched in 2021.

X-ray Diffraction (XRD) is a non-destructive analytical technique used to determine the mineral composition and crystalline structure of materials.

By analysing the angles and intensities of X-ray patterns, this system can identify individual minerals or compounds, determine crystal structures and phases and quantify the proportion of each phase in complex samples.

This cutting-edge capability delivers unmatched mineralogical testing with applications that include rock and soil mineral characterisation for geotechnical engineering, aggregate and binder evaluation for concrete and asphalt design, ore and tailings analysis for mining and beneficiation and quality control in cements and other engineered materials.

Uniaxial Compressive Strength (UCS) Test

The UCS test determines the maximum axial load a rock sample can bear before failure.

This test is crucial for assessing the strength and deformation characteristics of intact rock, and supports design decisions in excavation, tunnelling, and foundation engineering.

UCS is essential in geotechnical and mining projects for assessing the stability and strength of rock formations.

The UCS test measures how much axial (vertical) force a rock sample can withstand before it breaks—without any sideways pressure. This helps engineers understand the rock’s strength and how it will behave under load.

A cylindrical rock sample is drilled, prepared with smooth, level ends, and then loaded in a compression machine until it fails. The test follows international standards (ASTM and ISRM) to ensure accuracy.

The result, given in MPa, is calculated by dividing the maximum force by the cross-sectional area. Optional measurements like deformation can show how much the rock changes shape under pressure.

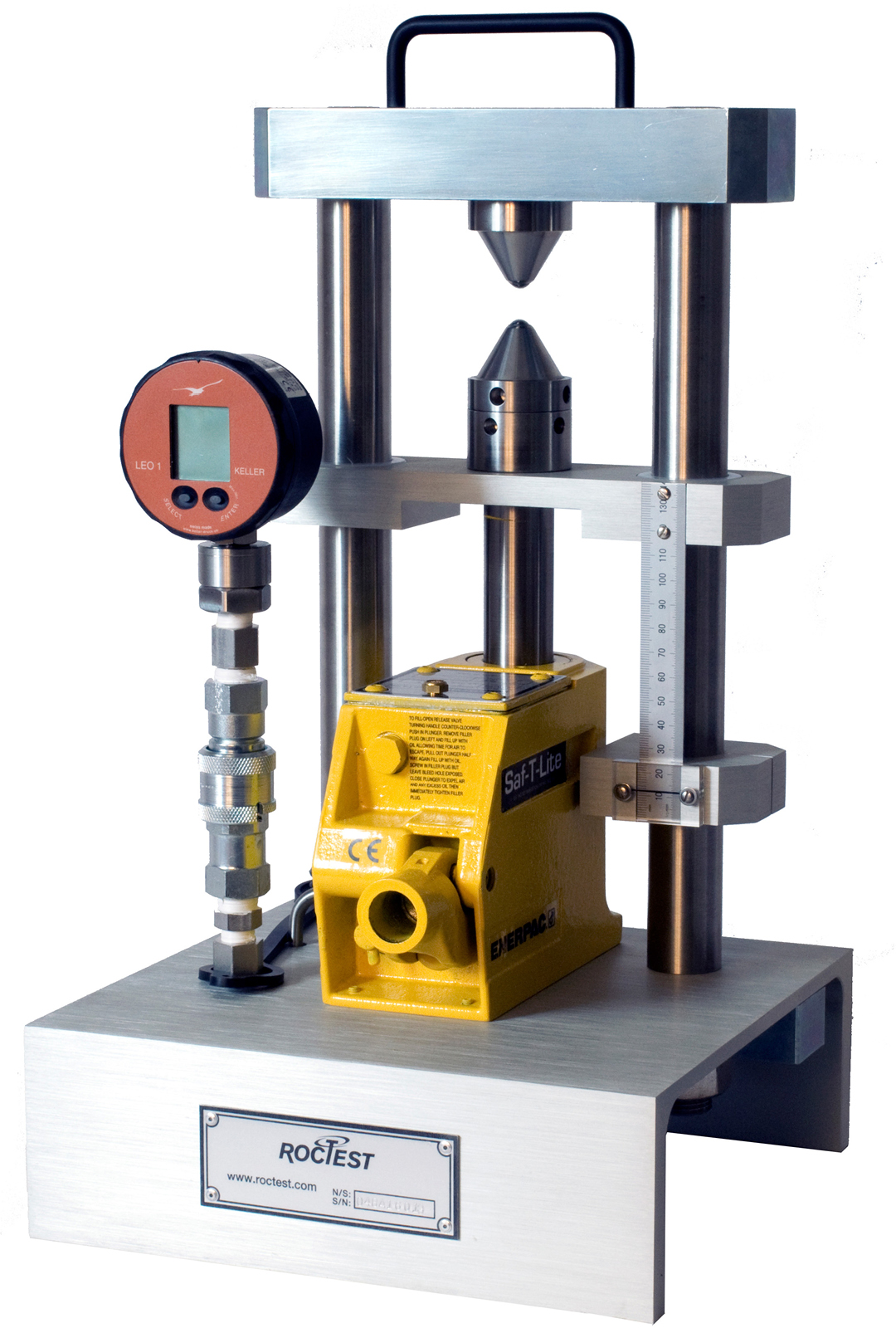

Point Load Test (PLT)

This is a fast and effective test used to classify rock strength.

PLT results can be used to estimate uniaxial compressive strength and tensile strength, especially when core samples are limited. It’s ideal for preliminary site investigations and rock classification.

The Point Load Test is a quick and cost-effective method used to classify rock strength. It’s commonly used in the field or lab to estimate key rock properties, including uniaxial compressive strength (UCS) and tensile strength.

Because the Point Load Test can be conducted quickly and with minimal equipment, it is an invaluable tool during early-stage investigations or when access to laboratory facilities is limited.

The method is widely used in mining, tunnelling, dam construction, and geotechnical design to provide rapid feedback on rock conditions before committing to more detailed and time-consuming analyses.

A rock sample is placed between two conical platens and loaded until it breaks. The force at failure is used to calculate the Point Load Strength Index which reflects the rock’s resistance to concentrated loading.

Key advantages include minimal or no sample preparation, suitability for irregular core samples, they can be performed in the field and requires correction for sample size.

Slake Durability Test

The Slake Durability Test is a fast, reliable tool for understanding how rock will perform in real-world conditions.

This test evaluates how well rock resists breakdown under wetting and drying cycles, simulating natural weathering.

It’s essential for predicting long-term durability in weak or layered rocks like shale, helping engineers assess slope stability and material suitability.

This test helps predict rock behaviour in slopes, embankments, and foundations, select suitable construction materials and assess long-term durability in weathering environments.

This test is especially useful for weak or layered rocks like shales, mudstones, and siltstones.

Following international standards (ASTM D4644 and ISRM), the test simulates natural conditions to assess long-term rock performance in the field.

High SDI (>90%) means the rock is durable and stable whereas low SDI (<60%) indicates poor durability and a higher chance of breakdown over time.